Features for

end user specifier architect features benefits

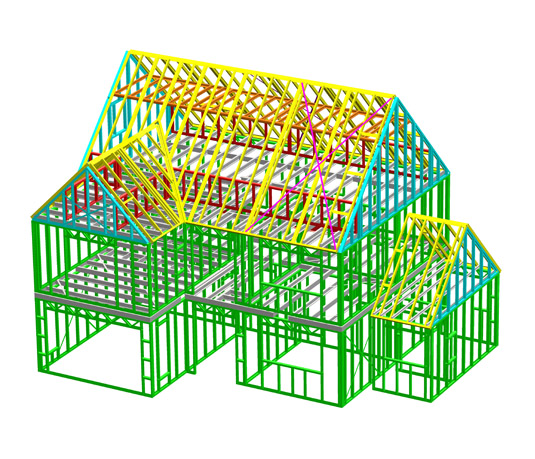

- Designed to meet or exceed NHBC guidelines. Certifications available if required – system is accredited by the Steel Construction Institute in accordance with BS 5950 Part 5 and NHBC Chapter 6.10

- 200 year + minimum expected life when used in a warm frame construction with supporting evidence backed up by the Steel Construction Institute, the NHBC, Tata Steel & Arcelor Mittal .

- 100 % recyclable with 50% scrap content steel used throughout – meeting Code for Sustainable Homes standard.

- Minimal packaging required during manufacture & transportation.

- SAP calcs performed on day of test will achieve same results 20 years later – all joints will remain as completed on day of installation.

- Lightweight construction means reduced foundation / piling requirements and also makes it a perfect system to retrofit to existing conversions.

- Reduced rafter/joist depth in comparison with traditional methods simplifies warms roof construction – advantageous when planning regulations restrict ridge height.

- Warm frame construction reduces risk of condensation and improves living environment – an A / A+ rating is achieved for this type of construction under the BRE Green Guide.

- Steel frame buildings at no further risk during lightning storms if earthed through consumer unit.

- Non combustible.

- Will not absorb moisture.

- “Room in the Roof” by default in most cases – typically providing more space than other systems.

- No interference from steel frame with respect to TV, radio, WiFi or other transmitted signals.

- Beneficial for areas subject to flooding due to inorganic nature of steel – structurally system not at risk nor will it need time to dry out – minimal disruption.

- In certain complex instances requirements for ridge, hip and valley steels is significantly reduced.

Features for

builder/developer

- Allows construction of the basic insulated structure to take place outside the “critical path”.

- Can be installed in wet or inclement conditions – unaffected by frost therefore minimising the risk of program slippage.

- In certain complex instances requirements for ridge, hip and valley steels is significantly reduced.

- Will not rot, warp, twist or creep under load nor be subject to insect infestation.

- SAP calcs performed on day of test will achieve same results 20 years later – all joints will remain as completed on day of installation.

- Ridges, hips and valleys completed with ease using patented U section profile.

- Manufactured in factory controlled conditions to tight tolerances providing a dimensionally accurate product to the benefit of following trades for following trades.

- Lightweight construction means reduced foundation / piling requirements and also makes it a perfect system to retrofit to existing conversions.

- Reduced rafter / joist depth in comparison with traditional methods simplifies warms roof construction – advantageous when planning restricts ridge height.

- Flexible and adaptable system permits late design changes to be accommodated.

- Reduced requirement for skilled tradesmen required to install.

- Lightweight gable panels can be installed removing risks associated with relatively fragile masonry gables.

- Steel frame buildings at no further risk during lightning storms if bonded via normal earth system.

- In many cases panels can be manually lifted into position.

- All site fixings & insulation panel joints are readily visible facilitating easy inspection of correctly installed product.

- Walls do not require external sheathing.

Features for

project manager

- A warm frame construction allows first fix trades to commence a lot sooner than traditional build reducing fixed site costs – up to 5 times faster than traditional methods of construction.

- Reduced construction phase insurance costs due to non combustible nature of material.

- In most cases the roof is capable of being erected at ground level and craned on – significantly reducing labour spent at height and therefore reducing H & S risks.

- Provision of safe working platform once floor joists installed and boarded.

- Relatively lightweight meaning reduced requirement for craneage.

- Reduced snagging due to lack of settling or shrinkage with call backs virtually eliminated.

- Manufactured in factory controlled conditions to tight tolerances providing a dimensionally accurate product to the benefit of following trades for following trades.

- 100 % recyclable with 50% scrap content steel used throughout – meeting Code for Sustainable Homes standard.

- Flexible and adaptable system permits late design changes to be accommodated.

- Can be supplied pre insulated depending on volume requirements further reducing on site assembly time.

- All site fixings & insulation panel joints are readily visible facilitating easy inspection of correctly installed product.

All our products are approved by the Steel Construction Institute